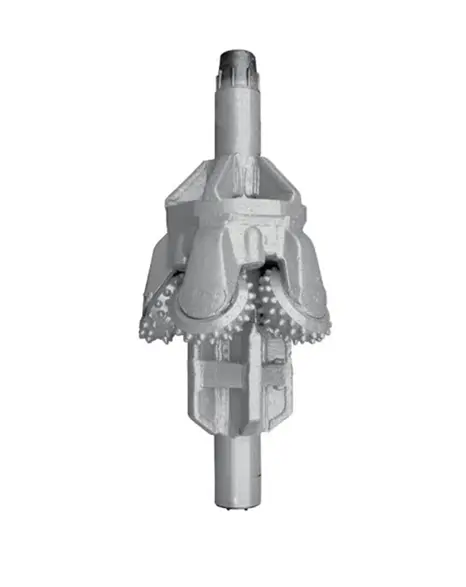

Rock Reamers are specialized drilling instruments used to widen pre-drilled holes in rock formations. They are built with strong materials and cutting structures to remove rock debris and generate greater borehole diameters. Rock reamers are widely utilized in the oil and gas, mining, and geotechnical engineering sectors for various applications such as wellbore expansion, foundation building, and underground excavation. These instruments are attached to the bottom of drill strings and spun to remove the surrounding rock, resulting in a smooth and consistent hole. These reamers are tested on several quality parameters to ensure they are free from defects. Rock Reamers come in a variety of sizes and combinations to accommodate varied drilling needs and rock forms.

| Specification | |

|---|---|

| IADC code: | 217,327,437,517,537, 617, 637, 737, etc |

| Sizes range: | 10" to 46" and customized according to drawings or requirements. |

| Pilot size: | 5 1/2",6 1/2",8 1/2",12 1/4" etc. |

| Bearing type: | Sealed or Open bearing. |

| Thread type: | REG/IF/FH/Pulling eye etc |

| 1. More suitable tooth type, bearing structure, sealing type and angle of inclination of paws. | |

| 2. More protection teeth on the roller cutters. | |

| 3. Perfect welding process prevents the damage to sealing and bearing system because of over beat. | |

| 4. Fully heat-treated alloy steel. | |

| 5. Professional engineers design Rock reamer for your drilling environment | |

| Applications: | It is suitable for the trenchless,no-dig,horizontal directional drilling(HDD), large size well,mining and infrastructure applications etc.

Our Rock reamer are promptly manufactured,we also custom manufacture reamers according to customers special request.The custom manufactured Rock reamer OD are between 10 inch to 46 inches. According to the features of drilling machine and different drilling formation. We adopt more suitable tooth type,bearing structure, sealing type and angle of inclination of paws.water cutting, good sand returning can efctivele reduce sand gathering. Unique anti-faling design of cones prevent the accident caused by falling cones which is leaded by bearing damage. Perfect welding process prevents the damage to sealing and bearing system because of over beat.The bit body adopts spiral design with good stabilizing and sand returning performance to improve hole opening speed reducing repeating rock breaking of cones. |